At this year's K 2019 in Düsseldorf from October 16 to 23, SCHWING Technologies will be presenting its extended vacuum pyrolysis system VACUCLEAN 0917 for the first time (Hall 9/booth A77). With this system, the German expert for environmentally friendly and energy-efficient thermal cleaning systems is primarily targeting users of especially tall filter candles and bundles up to 170 cm high and 90 cm in diameter. The SCHWING system includes a very large melt-off container, holding up to 150 liters of plastic in one application. The new vacuum pyrolysis system gently removes all plastic residues from very fine filters and guarantees filter qualities for the highest production results. Materials such as BOPP, PET and PC can be removed.

Safe and gentle vacuum pyrolysis

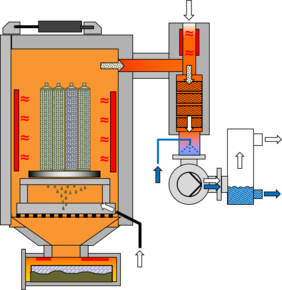

The fully automatic cleaning process of the VACUCLEAN 0917 takes place in an electrically heated vacuum cleaning chamber. The temperature is measured directly on the filter bundle, which is first heated slowly and gently. Here, a large part of the adhering plastic melts off and flows out. At approximately 450 degrees Celsius, the decomposition of the remaining material takes place. Remaining carbon is finally removed by carefully adding air (controlled oxidation). A sophisticated sensor system controls the entire cleaning process, so excess temperatures do not occur at any time.

Worldwide sales and testing at company headquarters

SCHWING sells its plants and complete process solutions worldwide. In Germany, the company also provides cleaning services and invites its customers to test the cleaning processes at its headquarters in Neukirchen-Vluyn. In order to achieve optimum results, the company is constantly developing its equipment and adapting its cleaning processes to new material mixtures and metal filter designs.